Ceramic ball bearings spin with very little friction. When you use CeramicSpeed ceramic balls in your derailleur pulleys and run them in super-slick coated hardened steel races, that little friction just about disappears. in your derailleur pulleys is an easy way to go faster. If you want the pulleys themselves to be even more resistant to wear, titanium is more durable than alloy, four times as durable. These CeramicSpeed Coated Ceramic Titanium Derailleur pulleys are designed for all 11-speed Shimano derailleurs, and they are better not only than Shimano’s offerings, but the CeramicSpeed Titanium pulley.

Friction Facts, a testing outfit, ran a pulley test. CeramicSpeed bearings won the test overall, beating nineteen brands of pulleys, with .033 watts of frictional drag per set. That’s dramatically better than Shimano Dura-Ace, at .159w. And killed Ultegra and 105. Every moment you’re pedaling, the CeramicSpeed bearings will take up less drag and help you move faster.

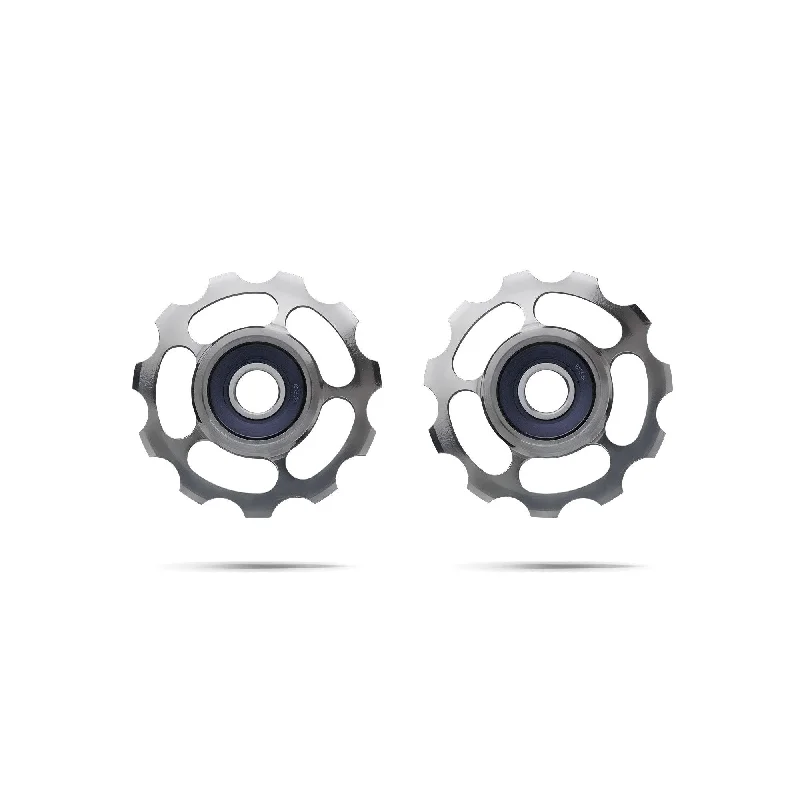

The specifics of Ceramic Speed pulleys are simple. The pulleys themselves are CNC-machined titanium, with cut-outs beneath the teeth both for dirt-clearing and light weight. Pressed into the opening are CeramicSpeed hybrid ceramic bearings. That means that the balls are ceramic and the races hardened steel. The titanium pulleys should out-live aluminum pulleys, which should out-live plastic pulleys, and the bearings should outlast conventional sealed races by an order of three to five times the service life.

CeramicSpeed utilizes Grade 3 Silicon Nitride balls that possess the best possible surface finish and roundness. In testing, the balls are 400% smoother, 128% harder, and 58% lighter than standard steel balls found in most bike components. They’re more than 100% smoother and 15% harder than standard ceramic balls. The balls are installed into hardened steel races in dust-free clean rooms and then checked again before assembly is complete.

Part of CeramicSpeed’s commitment to having the lowest-friction bearings on the market is keeping up their research and development. That led them to a special metallic coating that can be applied three microns thick on the races. It makes the treated surface 80% harder than hardened steel. In terms of friction, the already low-friction CeramicSpeed bearings with the treatment see friction reduced by over 50%. In terms of service life, these coated bearings last even longer, like over 60% longer, than the standard CeramicSpeed bearings. Better yet, the coating means the races better resist contamination from water, dirt, degreaser, etc. Aka, the risk of bearing failure due to corrosion has been reduced to near zero. They can even run without grease or oil, though CeramicSpeed recommends their oil for longer life and lower friction.

Installing them is easy. All you need is a 3mm Allen head tool. There’s an upper pulley and lower pulley. Make sure you put them in the right places. The upper is a bit narrower to make centering less important. The logo is placed inwards, aka to the left. The pulleys should be serviced periodically with a little thin oil, by putting a drop or two on the tiny gap between the seal and the edge. CeramicSpeed suggests doing this each time you lube the chain, or after a bike cleaning, or after riding in mucky conditions. This will lengthen the life of the bearings and keep frictional drag at the minimum.

The kit comes with two pulleys, spacers, CeramicSpeed oil for lubing the bearings, and a sticker sheet.

CeramicSpeed Coated Ceramic Titanium Derailleur Pulleys for Shimano 11-Speed derailleurs the closest thing to nothing between your legs and the rear wheel.